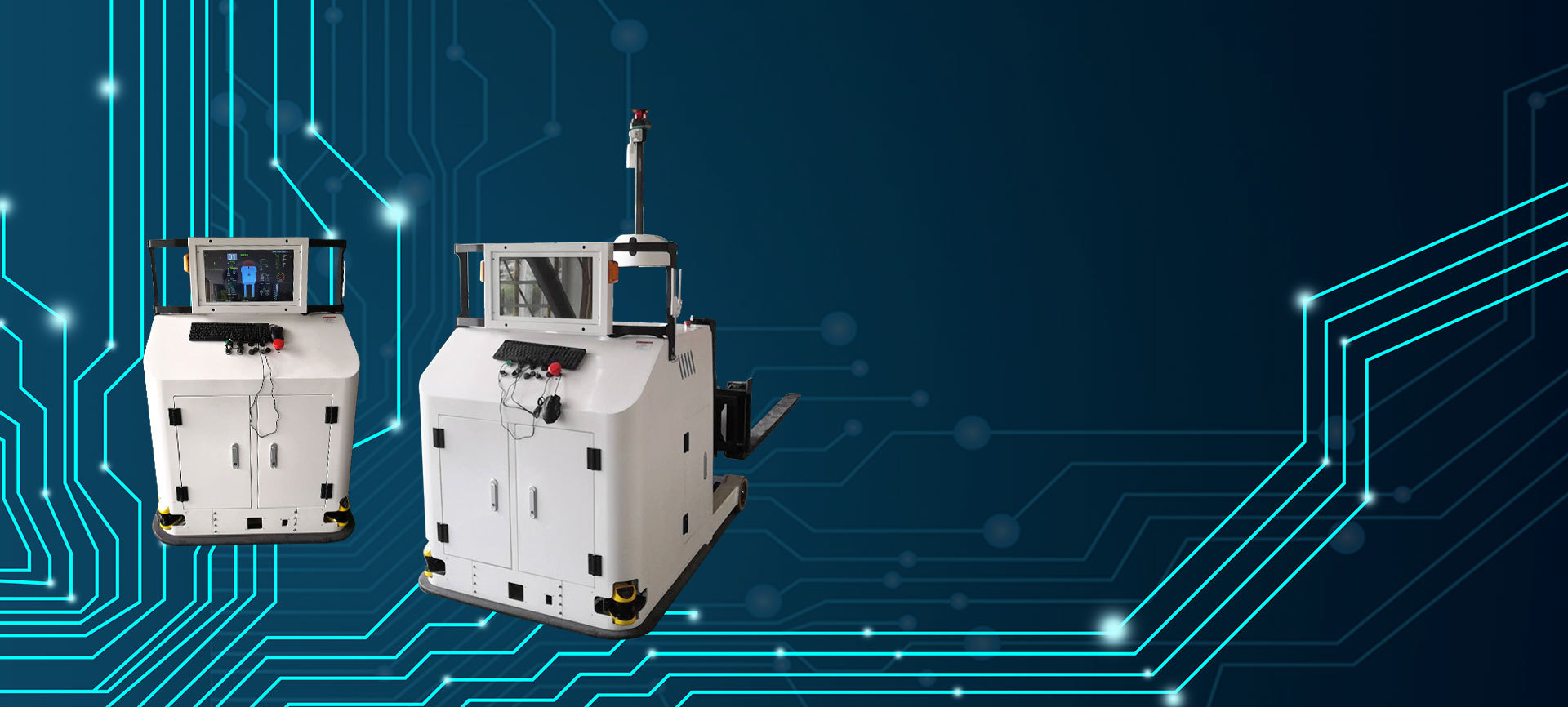

Engine transmission engine assembly

|

Environmental conditions: |

|

Ambient temperature: -10-40 ℃ |

|

Basic road conditions: |

|

Pavement requirements: outdoor |

|

Drive unit: |

|

Steering wheel drive |

|

System structure: |

|

AGV dispatching system, AGV, automatic charging pile system |

|

Communication equipment: |

|

Wireless WIFI |

|

Power supply system: |

|

48V / 80Ah lithium battery / online intelligent charging |

|

Transport process: |

|

The AGV automatically runs to the loading point and stops after receiving the calling information. After manual loading and unloading tools are loaded, the button releases the AGV. AGV passes through the corridor along the established route and automatically runs to the unloading point of the warehouse. It is manually unloaded and returns with an empty pallet after completion. |

|

Customer benefits: |

|

Unmanned transfer of finished products from engine and gearbox assembly line to warehouse. |

|

Solution advantages: |

|

1. Outdoor magnetic nail, indoor magnetic stripe, hybrid navigation |

|

||||||

|

||||||

|